BOSOM ALE high thermal conductivity carbon alloy debut -- open the door of the lamp radiator "plastic instead of aluminum"

Release time:2022/11/29 Publisher:

In the 8th Shanghai International Automotive Lighting Exhibition (ALE), BOSOM New materials, as one of the pioneers of plastic aluminum with high thermal conductivity carbon alloy in China, was crowded and endless in the small booth. Dr. Shen Bo of BOSOM New Materials shared the application of BOSOM high thermal conductivity carbon alloy in the car lamp industry in the "2022 Intelligent Car Lamp Innovative Technology Application and Intelligent Manufacturing Technology Forum". Hundreds of industry elites are attracted by the innovative application of BOSOM's new material "plastic instead of aluminum", and praised by auto lamp industry experts: it has led a new direction for lightweight, low carbonization and cost reduction of auto lamps.

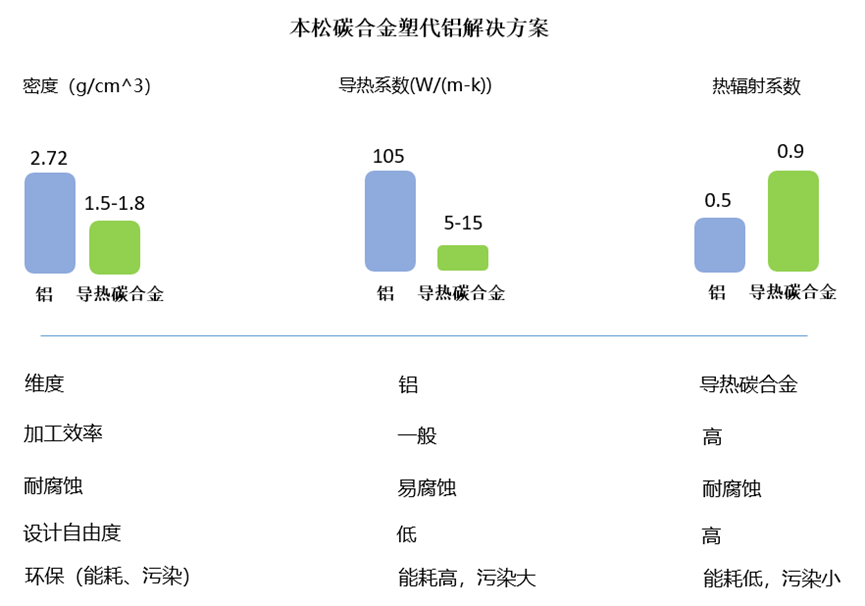

The high thermal conductivity carbon alloy material developed independently by BOSOM New Materials for ten years,it can often directly replace metal aluminum as heat dissipation parts, breaking through the traditional heat dissipation parts mainly rely on aluminum and other metal materials shackles,it breaks the monopoly of high-end cooling plastics by multinational companies.Compared with international similar materials, it not only reduces the cost about 30%, but also has better thermal conductivity, processing and conventional mechanical properties.At the same time, the technology of this product has been identified as the international advanced level by China Light Industry Federation, and it has been identified as the first batch of new materials in China by Zhejiang Provincial Department of Economy and Information Technology.BOSOM New Materials has cooperated with SAIC Passenger Car, Shenzhen BYD, Nio and other well-known enterprises in the industry. Under the joint efforts of industry experts and material engineers and structural engineers of BOSOM, the "plastic replacement of aluminum" headlight radiator has been verified and applied in batches on several models, reducing the cost of customers about 20%+, reducing the weight about 30%+, and improving the stability of the supply chain. For the lamp industry, it opened the door of the "plastic replacement of aluminum" lamp radiator.

In the future, BOSOM will continue to learn from domestic and foreign excellent enterprises, adhere to independent innovation and the combination of production, education and research, to improve the comprehensive performance of materials.Summarize material characteristics, insight into the industry pain points, work with excellent customers to understand the product in use, experiment, molding and other scenes, break through the structural design problems together, and constantly break through and improve the application of high thermal conductivity carbon alloy in LED lighting, security monitoring, communications electronics, aerospace, 5G base stations and other fields.At the same time, learn from each other with outstanding colleagues in the industry, together with the challenge of the world's plastic generation of aluminum heat dissipation king, for energy saving and emission reduction and solve the "neck" problem.

浙公網(wǎng)安備33011002011562號

浙公網(wǎng)安備33011002011562號 Mail

Mail Office System

Office System